Porcelain sinks, frequently the shining focal factor in kitchens or lavatories, carry a sense of elegance with their easy, smooth surfaces. Yet, for many, the thought of drilling into such a sensitive fabric can ship a shiver down the spine. Understandably so—porcelain, whilst durable in each day use, can shatter or crack if handled with even a hint of impatience. But fear not. With the proper approach, equipment, and methodical guidance, developing a easy hole in a porcelain sink is absolutely within reach. This manual will lead you, grade by grade, thru the method, ensuring now not simply achievement but a smooth, subtle end result that appears as although it turned into completed with the aid of a professional. Drill Hole In Porcelain Sink.

Understanding Porcelain Sinks: What You Need to Know Before Drilling

Porcelain is a cloth of contradictions. It’s hard—resistant to stains, wear, and the each day assaults of kitchen life—but satirically brittle with regards to drilling. Beneath that clean, inviting glaze lies a rigid surface that, whilst pressured the incorrect manner, can fracture with alarming ease. Porcelain sinks are often crafted by way of layering the porcelain over a metal or ceramic middle, developing an exterior that’s as sensitive as it’s miles strong. The glaze that gives porcelain its unmistakable shine is also what makes drilling a task. Each drill skip need to be calculated and specific. A misstep here could lead to cracking, or worse, shattering. Proper understanding of this delicate dance is important to fulfillment.

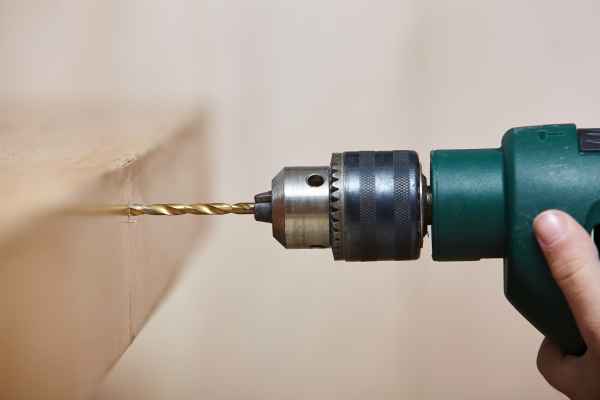

Tools and Materials Needed for Drilling a Hole in a Porcelain Sink

Not all equipment are created identical, in particular when you’re working with porcelain. The crown jewel of your toolkit? A diamond-tipped drill bit. Ordinary drill bits certainly aren’t as much as the undertaking; porcelain’s toughness will blunt them fast, turning a easy assignment right into a near-impossible chore. Alongside this specialised bit, you’ll need a cordless drill with variable speed manage for finesse. A lubricant—whether water or a mild oil—plays the crucial position of maintaining the bit cool, preventing overheating. Masking tape, a marker, and a center punch make sure precision, at the same time as protection goggles guard you from potential flying particles. These gear paintings together like an orchestra, each gambling its part to make sure a easy, specific hollow.

Preparing to Drill: Setting Up Your Workspace

Preparation is everything. A well-prepared workspace makes all of the distinction among fulfillment and frustration. Begin by means of drying your sink thoroughly. Even the tiniest speck of moisture or dirt should intervene together with your drill’s precision. Lay down a gentle material around the vicinity to cushion any falling debris and guard nearby surfaces. Arrange your tools in order that the whole thing you want is inside easy reach. Bright lights is non-negotiable—you want to peer exactly in which that drill bit is going. Lastly, double-take a look at that your drill bit is securely fixed in location. In this sensitive operation, there’s no room for unfastened additives.

Marking the Spot: How to Determine Where to Drill

Precision is paramount. Start by way of applying a strip of covering tape to the location wherein the hollow might be drilled. This tape prevents your drill bit from slipping at the sink’s glossy surface. Now, degree cautiously—each millimeter topics. Once you’re confident on your measurements, mark the spot with a small dot the use of a marker. To create a guide on your drill bit, lightly faucet the marked spot with a middle punch or a small nail. This indent will preserve the bit from wandering, ensuring your drill remains precisely in which it needs to be.

Starting Small: The Pilot Hole Technique

The pilot hole is your mystery weapon towards cracked porcelain. Begin with a smaller diamond-tipped drill bit and slowly drill into the marked spot. This small pilot hollow acts as a manual for the bigger bit, stopping any unexpected slips or cracks as you pass forward. Keep the drill at a low velocity, making use of mild stress. Don’t rush. The purpose is to allow the drill bit do the paintings, progressively sporting thru the porcelain’s tough outer layer. Once the pilot hole is in vicinity, you’ll have a clear route for enlarging the hollow to an appropriate size with a larger bit.

The Drilling Process: Step-by-Step Instructions

Now, the actual paintings starts. Start drilling slowly, retaining a steady hand and applying mild stress. Don’t push the drill; permit it to float thru the porcelain at its very own pace. Frequently pause to use water or mild oil—this cools the drill bit and minimizes friction, that’s vital in stopping cracks. If you feel the bit overheating, prevent immediately and permit it settle down. Gradually growth the hole’s size with the aid of switching to large bits, however always drill at a gradual pace. Rushing will handiest lead to catastrophe—cracks, chips, or maybe shattered porcelain. Patience is fundamental right here, ensuring that every bypass of the drill is clean and controlled.

Dealing with Common Challenges While Drilling

Even the most cautious practise can’t take away all potential problems. Overheating is a not unusual problem which could lead to hairline cracks within the porcelain, so preserving the drill bit cool is vital. If the bit begins to slip on the porcelain’s glossy floor, double-test that your protecting tape is in vicinity, and that your indent is deep sufficient. Another assignment is the small chips that may form across the hollow. Don’t fear—those can commonly be smoothed out later. Above all, hold your composure. When faced with problems, a peaceful, methodical technique will see you through.

After the Drill: Finishing Touches and Cleaning Up

The hole is drilled, but the activity’s no longer over. The edges of the hollow may be rough, so take a best report or sandpaper to easy them out. This step now not best protects the fixture you’ll be putting in however also gives the hole a clean, professional finish. Wipe the vicinity down with a humid material to take away any lingering dust or debris. Now is the time to carefully inspect the hole. Are there any chips or cracks? If now not, congratulations—the hardest component is over. All that’s left is to install your fixture.

Mistakes to Avoid When Drilling into Porcelain

Drilling into porcelain is a undertaking that needs admire and care. Using the wrong tools—along with a wellknown drill bit—will almost absolutely damage the surface. Rushing the system, drilling too speedy, or applying an excessive amount of pressure can result in cracks which might be not possible to repair. Failing to cool the bit for the duration of the drilling technique is another commonplace mistake that could lead to catastrophe. The key to achievement is patience. Take a while, use the proper gear, and stay vigilant at some point of the system.

Enhancing Your Sink: Installing the Fixture

With the hole now complete, it’s time to put in your fixture. Whether it’s a new faucet, soap dispenser, or some other accessory, the system is straightforward. Insert the fixture through the hole, making sure a snug match. Follow the manufacturer’s commands carefully to stable it in region. Applying a small bead of sealant across the base is a superb concept to prevent water from seeping in. Once the whole lot is installed, test for leaks and tighten any loose additives. A nicely mounted fixture will now not handiest beautify the sink’s capability but also increase its appearance.

Maintaining Your Porcelain Sink After Drilling

Your porcelain sink, now ready with its new fixture, requires a piece of care to hold it looking pristine. Clean it often with a non-abrasive purifier to avoid scratching the floor. Harsh chemicals can stupid the end, so persist with moderate, mild answers. Keep a watch at the drilled hollow—look at it periodically for any symptoms of damage or cracking, specially if the fixture is concern to heavy use. With a bit attention, your porcelain sink will maintain to polish, serving each as a practical and aesthetic characteristic for your space for years to come.

Conclusion

Drilling into porcelain may additionally appear like a frightening mission, however with the right equipment and a affected person technique, it’s entirely doable. Understanding the cloth, getting ready your workspace, and using a step-by-step approach are all crucial for a successful final results. By averting not unusual pitfalls and taking the time to get it right, you’ll attain a easy, professional end result. Whether you’re putting in a new faucet or any other fixture, your porcelain sink will continue to be a lovely and purposeful detail in your house.